CAF (Cavitation air flotation), is a patented solid-liquid separation technology especially used for removing oil and grease, jelly and SS. By using of aerator, CAF’s special designed impeller can distribute the micro bubbles into the sewage evenly without any complicated air dissolving process. Then this will not have any blocking phenomena.

- +86-0510-85950018

- sales@wxgyhj.com

(1) CAF Introduction

CAF (Cavitation air flotation), is a patented solid-liquid separation technology especially used for removing oil and grease, jelly and SS. By using of aerator, CAF’s special designed impeller can distribute the micro bubbles into the sewage evenly without any complicated air dissolving process. Then this will not have any blocking phenomena.

(2) Features

※No need of reflux pump, air compressor and pressure vessel

※save operating cost, floor space and investment cost

※simple, compact and maintenance-free

※especially suit for oily wastewater treatment

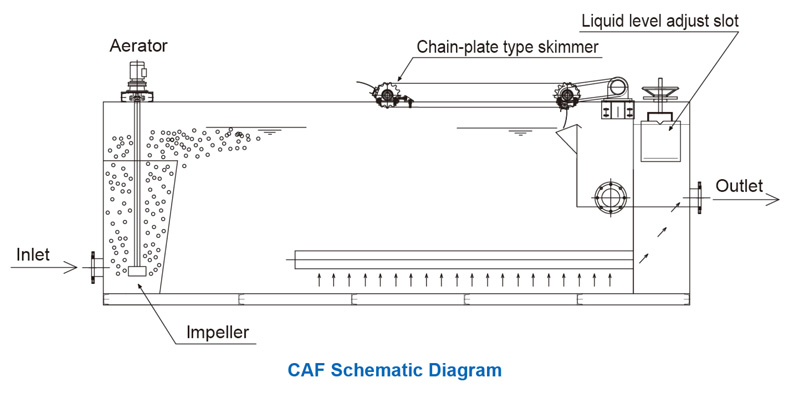

(3) Working principle

CAF (cavitation air flotation) is composed of aerator, flotation tank, skimmer and electric cabinet. The aerator will generate air bubbles through its highly speed rotating motor by way of absorbing air and then this micro bubbles will be distributed in the sludge water tank via stainless steel bulk air impeller.

Utilizing the centrifugal force caused by high speed rotating driven impeller, aerator produces negative pressure and suck other gas into aeration port. Then the air is released again by submerged aeration port. When the bores on the perforated impeller produce bubbles, high speed rotating impeller will cut bubbles into 30-100um tiny bubbles. Finally, flocculating sewage mixes up with these micro-bubble after entering into the flotation tank. Then these micro-bubbles attach to the suspended solids and float them to the surface. These suspended solids reply on the micro-bubbles to sustain the water surface, forming a floating layer on the surface of the unit. The floating layer is removed into scum tank by means of a skimming device.

(4) Application

Cavitation air floatation is suitable for:

※Disposal of oily wastewater in petrochemical industry

※Oily wastewater treatment and reinjection water in oil exploitation industry

※Disposal of slaughter wastewater in meatpacking industry

※Grease and effluent treatment in dairy industry

※The treatment of effluents generated by pulp and paper industries