Our multiphase mixture DAF, also called air-liquid mixing pump DAF, uses the multiphase pump (such as Japanese Nikuni, Germany Edur pump) to produce micro bubbles, without requiring of air compressor and dissolved air tank. Due to its special hydraulic parts design, the pump can fully mix up with the liquid in a highly dispersed state, like a dynamic mixer.

- +86-0510-85950018

- sales@wxgyhj.com

(1) DAF Introduction

Our multiphase mixture DAF, also called air-liquid mixing pump DAF, uses the multiphase pump (such as Japanese Nikuni, Germany Edur pump) to produce micro bubbles, without requiring of air compressor and dissolved air tank. Due to its special hydraulic parts design, the pump can fully mix up with the liquid in a highly dispersed state, like a dynamic mixer.

(2) Features

※No need of air compressor and pressure vessel

※Save operating cost, floor space and investment

※simple,compact and maintenance -free

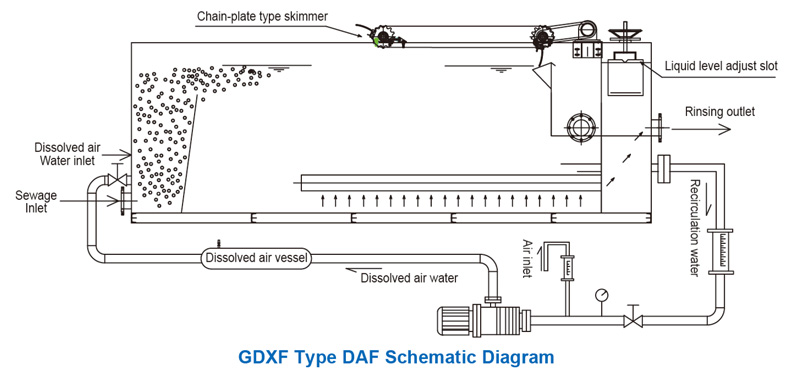

(3) Working principle

The performance of GDXF is mainly determined by the gas content in the multiphase mixture liquid. When pump inhales liquid, it forms negative pressure at the pump inlet where air is inhaled through suction hole and liquid. Then air is dissolved into water by high speed rotating pump impeller. By adjusting operating points and solid-liquid proportion, it can achieve massive dispersed micro-bubbles or meet maximum carrying capacity. Based on different pump specification, gas content in liquid can reach 30%. When this saturated water (over-saturated water) flows into dissolved air vessel, it can instantly release high-density micro-bubble whose average diameter is less than 30 through release device after a certain period of time.

Finally, flocculating sewage mixes up with these micro-bubble after entering into the flotation tank. Then these micro-bubbles attach to the suspended solids and float them to the surface. These suspended solids reply on the micro-bubbles to sustain the water surface, forming a floating layer on the surface of the unit. The floating layer is removed into scum tank by means of a skimming device.

(4) Application

GDXF Type dissolved air flotation is suitable for:

Disposal of oily waste water treatment in petrochemical industry

Oily waste water treatment and reinjection water in oil exploitation industry

Disposal of slaughter waste water in meatpacking industry

Grease and effluent treatment in dairy industry

The treatment of effluents generated by the pulp and paper industries

Oily waste water treatment in machinery processing industry